This site is a reference to Jesse G. Lindeman and the Lindeman – John Deere BO Crawler along with other equipment that was designed and built by Jesse and his three brothers Harry, Ross & Joe at Lindeman Power Equip. Co., Northwest Equip. Co. & Lindex Co. in Yakima, Washington between 1921 and 1998.

If you can add anything to this site or if I have stated something incorrectly please E-mail me at ********@***oo.com” href=”mailto:li********@***oo.com” data-original-string=”BQappIOjb7Z/sXHeahqecw==e57jaBmuHDMOe8UA+dFMy949ZqfZY5tU0K+DD2YCn25xnY=” title=”This contact has been encoded by Anti-Spam by CleanTalk. Click to decode. To finish the decoding make sure that JavaScript is enabled in your browser.”>li********@***oo.com with any comments or suggestions.

Thank you

Ted E. Adams

(P.S., For those interested, Click Here for a short autobiography of Ted Adams.)

Jesse’s stay in the armed forces was short. The war ended, and he was released from duty in July of 1919. After returning home, he could not envision himself as a “farmer”, so he ventured out west to Ellensburg, Washington where his Uncle, Gus Lindeman, had an auto dealership and was also the local sheriff. Jesse moved to Yakima and was hired as a farm implement salesman at Rovig Lumber Company. He started to work on the first working day in January of 1920.

In those days the lumber company was like a general store, selling everything from nuts and bolts to equipment. Rovig handled trucks, farm implements, lumber, and the Moline Plow Line, which included the Moline Universal Tractor. There was a place for their tractor in the orchards of the Yakima Valley, but the tractor was too high to get close enough to the trees. Jesse soon saw a need for a ditcher and took off his salesman’s hat to design and build one. The first model was horse drawn. It was then adapted to pull behind truck or tractor. The next improvement was to add cast wheels for depth control and to repack the ditch. The final improvement was to add a mechanical lift to bring the discs out of the ground for transport.

In the meantime, Jesse saw a need and designed and developed the Extension Disc for the tractor. The apple trees were so big with low branches the tractor could not get close enough to do a good job of discing. This disc enabled the tractor to drive down the center of the row and disc both sides. It was adjustable to allow for different row widths.

Things were going well for him, so he wrote home and talked his younger brother Harry into coming to Yakima to work for Rovig also. In April of 1921, Harry made the move and he too went to work for Rovig Lumber Company. Unfortunately even though the disc sales were doing well, Rovig Lumber went out of business in 1922. This was a great opportunity for the Lindeman brothers. Jesse and Harry then decided to combine their savings purchasing the parts and equipment valued at approximately $4,000 at the Rovig auction for $158.00. They then added another $150.00 to rent a building and buy some tools, starting their own small manufacturing and retail farm machinery business. They were in need of a crawler tractor for orchards, so Jesse traveled to Spokane and secured the Holt Caterpillar dealership from the branch managed by Ben C. Holt. They named their company the Holt Tractor Agency. They sold a few of the two ton T-35’s and T-29’s and one of the ten ton loggers. Their chief income, however, was derived from making and selling a Disc Harrow, which was attached behind the Cletrac and Fordson tractors. They began to experience great hope for the future, so they adopted the rather long and somewhat impressive name of LINDEMAN POWER EQUIPMENT COMPANY. There were, of course, several times within the next few years that they wished they had their original total capital back of approximately $300.00. However, they had no recourse but to hang on. They developed other equipment that was either too expensive to bring back from the east or that was not suited for the specific needs of the Pacific Northwest.

In 1925 when Holt and Best merged to make Caterpillar, they wanted the Lindemans to remain their dealer. Jesse and Harry would have to put up $5,000.00, but because they didn’t have $500.00, let alone the needed $5,000.00, they lost the dealership. Lew Acoff, an old Holt man in Spokane, told them that Cletrac had just released a new tractor, the Model K. He suggested they try for the dealership. Jesse left for San Francisco by passenger ship, the H.F. Alexander, out of Seattle, to meet with the Western Sales Manager of Cletrac. He came home with the franchise. This tractor was a perfectly designed tractor for orchard work and from the beginning had very few service problems. They became one of the larger dealers in the area. A third brother, Ross, joined Jesse and Harry’s venture.

They needed more room, as their company was rapidly growing; so they rented the former Cadillac dealership building located on South First Street in Yakima. They added to their inventory a disk furrower, tractor brush rake, trailer for hauling fruit out of the orchard, the Friend Sprayer line and the Mack Truck Line. Business was so good, that in 1927, they purchased a dealership in Wenatchee. Harry moved there to manage its operation. In 1928, they purchased about one and a half acres of property (which grew to about 10 acres) on south third street and built a 150″ x 150″ building that was the first of three sections of the Lindeman Power Equipment building that they stayed in until John Deere purchased them in 1946. After construction of a new building on south third street, they moved the business in 1930, to the new building. They had branch plants in Wenatchee and Ellensburg.

At about the same time, Mr. Rollin K. White, who owned and ran Cletrac, began “tinkering” with the design of the tractor. It wasn’t long before they found their service trouble mounting. Also, about then rubber tires appeared to hold some promise for wheel tractors and competition from the Caterpillar 10 and 15 caused them to look into the handling of a wheel tractor. In 1930 Lindeman Power Equipment Company became dealers for John Deere. In April, Harry was coming back from a meeting in Canada. His new car slid off a steep embankment near Chelan, Washington. He died in the crash. This was a high and low year for the company with the high of a new building and becoming a John Deere dealer and the low of losing Harry. A real need for the Yakima area was a low-to-the-ground tractor like the Cletrac to work in the orchards, so they took a John Deere GP Standard and modified it to work.

John Deere took notice and adopted it, eventually it became their GPO Model tractor. The John Deere tractor ran very well on distillate, kerosene, good grade furnace oil, light grade fuel oil, at a cost of about 6 cents per gallon which looked awfully good to the average farmer during the depression period. Jesse had thought a lot about putting tracks on a John Deere, so in 1932 he put a pair of Best tracks and rollers on a John Deere Model D. They had built 3 or 4, when word got back to John Deere.

Colonel Wiman the head of John Deere, was a man of vision and apparently requested that one be sent back to Moline for a demonstration. So they sent one back to JD with Jesse to demo it. It was a raw cold day, Jesse drove it onto a log and spun it around, Col. Wiman was ecstatic. By the way, he wasn’t known as the Colonel yet. When the demo was over, Jesse and the Colonel went back to his office and warmed their cold feet up on the radiator. He then told Jesse that they were discontinuing that model of D. Jesse said it was all worth it. “There I was, just a little dealer, warming my feet with thee top man at John Deere, Charles Deere Wiman.”

With that, Jesse went about designing tracks for the GPO. They built about 26 before Deere stopped producing them. In 1934 Joe, the 4th and youngest brother, came out and joined Jesse and Ross.

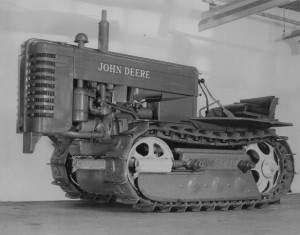

H. G. “Pat” Murphy, (a cousin of Colonel Wiman) was the branch manager of the Portland, Oregon branch. Ben Keator his sale manger could see a need for a tractor with tracks in order to stay in competition with Caterpillar. They told Jesse that they could get a new Model BO orchard chassis and would he design it to take tracks? Upon receiving the chassis, it took about a year to complete the first Model BO Crawler Tractor. It was field tested at the Congdon Orchards in Yakima, where, unfortunately, the orchard was mostly flat ground. They started the first production of crawler.

The first ten units produced had metal-to-metal plates that operated in oil. Two crawlers were sold to a McMinnville, Oregon customer who had all hillside fields. Trouble started shortly after. In McMinnville, the farmer was on all side hills and had to constantly pull the lever to keep his line, the metal plates started to flake metal particles and fill between the plates and would not let it disengage. Jesse was up against a brick wall. He had paid off Deere and the other creditors so he couldn’t buy the tractors back. He had to make them work. He also heard that 6 other crawlers were having the same problems. He solved the problem with Chevrolet dry clutch plates riveted on about half the existing steel plates. In order to get by until the conversion package was ready, he had them drain the oil, flush it out then fill it up completely with fresh oil. This gave him enough time for the younger brother Joe to take the conversion out and install it. Fortunately, the crawlers were within a short distance from Yakima, so Joe could replace a kit on one or two (mostly in overnight trips), bring the old parts back to the plant and deliver another one to another location. This procedure solved the problems and it in turn made the Lindeman a better tractor.

Once that problem was solved, the production started, they improved the crawler and tried to get a contract with the government. They built a prototype for a demo. Sadly they were unsuccessful in being awarded the contract.

The Lindeman Brothers continued to make crawlers and improve them and developed a third model. Most of their income was from other implements, not the crawlers at this time. These next photos show part of the equipment they were building.

their income was from other implements, not the crawlers at this time. These next photos show part of the equipment they were building.

They built the orchard trailer, and if you notice, young ladies are driving them. The crawlers were easy enough to drive, that was there job. Even though the government contract was not theirs to be had, still a few went to the Navy.

They built the orchard trailer, and if you notice, young ladies are driving them. The crawlers were easy enough to drive, that was there job. Even though the government contract was not theirs to be had, still a few went to the Navy.

They built many versions and sizes of land rollers, brush rakes, and planters, along with a few pea rakes. Other big items were the transplanter and sprayers.

The sprayer started off with a small two-horse model ground-powered with a Friend Pump. Then to a PTO powered 400, 600, & 800 gallon unit, most with offset wheels like the Orchard Trailer, to allow for the rolling over the ditches with minimal jar to the loads.Some models even had tracks to make it an even smoother ride. They also had a subsoiler.

They designed a single bottom rollover plow to fit on the Ford tractor with the Ferguson Hitch. Ferguson bought some which worked so well, that he gave Lindemans a contract for 10,000. They would load a truck or rail car, get the bill of lading, take it to the bank, getting $18.60 for every one shipped. This made a profit of $8.00 per plow.

This was a very unique plow for the day because when you got to the end of the row there was nothing to trip or do but raise it out of the ground and turn around. When you raised the plow it would trip a lever and the weight of the plow would allow it to turn over, locking it into place when you set it down. The first model had two coulters’, the second model was designed with a single coulter that was attached with an adjustable casting. The third model was a big change, with its cast top link, frame and trip arm.

With the threat of war, the hop farmers were concerned that they wouldn’t be able to get their hops picked because the government wouldn’t let the Canadian Indians come across the border to work. A local farmer, Bill Gamache, heard about a hop picking machine being built in California.

He went down and talked the manufacturer into selling him two machines and had them shipped to Yakima.They worked fairly well, so when the designer was in Yakima, Bill talked Jesse into getting the manufacturing rights. There were no drawings, so Jesse took one of the machines and cut it down the middle and laid it out on the showroom floor so that drawings and welding fixtures could be made.

He went down and talked the manufacturer into selling him two machines and had them shipped to Yakima.They worked fairly well, so when the designer was in Yakima, Bill talked Jesse into getting the manufacturing rights. There were no drawings, so Jesse took one of the machines and cut it down the middle and laid it out on the showroom floor so that drawings and welding fixtures could be made.

Once the war started, John Deere and Lindeman Power were making parts for the war effort. Lindeman Power was building parts for the Navy’s Water Buffalo. While Deere production of tractors was practically shut down during World War ll, they were able to get priority from the War Production Board for these tractors, which allowed Deere produce the chassis. Jesse had to place an order for five hundred of the chassis, John Deere would run the complete order and ship them as they were needed. By this time they had become manufacturers as well as retail tractor dealers with Disc Harrow, Furrowers, Brush Rake, Trailers, Sprayers, etc.

Once the war was over, the little Lindeman Crawler really took off. They even had to put in a RR spur line and a new loading dock. John Deere would send 30 chassis on a railroad car. A total of approximately 1675 chassis were shipped to be made into Lindeman Crawlers. There were more then that built because a kit was sold to convert a wheel BO into a crawler. Even though they were busy with all the crawler business, they would still listen to the customer and build what was needed even if it wasn’t going on a John Deere. Here are some photos of a hydraulic system and a tool bar built for the Caterpillar tractor and a special modification for the BO Crawler to go into the the celery fields along with different types of winches, and many more special tools the farmer needed.

Once the war was over, the little Lindeman Crawler really took off. They even had to put in a RR spur line and a new loading dock. John Deere would send 30 chassis on a railroad car. A total of approximately 1675 chassis were shipped to be made into Lindeman Crawlers. There were more then that built because a kit was sold to convert a wheel BO into a crawler. Even though they were busy with all the crawler business, they would still listen to the customer and build what was needed even if it wasn’t going on a John Deere. Here are some photos of a hydraulic system and a tool bar built for the Caterpillar tractor and a special modification for the BO Crawler to go into the the celery fields along with different types of winches, and many more special tools the farmer needed.

In 1946 Deere advised Jesse that they were going to discontinue the Model BO. It was suggested they would welcome the pursuit of the possibility of converting their new Model M to tracks. They sent him a Model M chassis, and he converted it into a crawler.

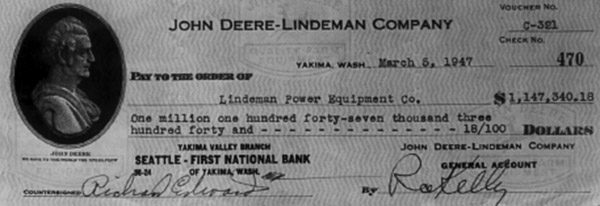

Col. Wiman along with P. Murphy came out in November of 1946 to see the conversion Jesse had done on the Model M. They ended up having a race between a BO and the newly converted Model M Crawler. Wouldn’t you know it the Col won and it wasn’t because he was the boss, the BO has a faster gear ratio. Upon completing the Model M conversion, Deere and Company made an offer to purchase Lindeman Power Equipment Company. This put Jesse up against that brick wall again because the Federal Trade commission was about to step in due to the Deere-Ferguson rivalry. Jesse knew he could still make the deal with Deere and not include the plow or the hop picker. Jesse and Joe purchased 10 acres of property on South First Street and started Northwest Equipment Company in order to finish the already placed orders for the plows and hop pickers. Deere and Company took control of the plant on January 1, 1947. On December 28th prior to the takeover, the steel foundry caught on fire and burned to the ground (a $50,000 loss that was covered by insurance). The rest of the plant was not damaged.

Col. Wiman along with P. Murphy came out in November of 1946 to see the conversion Jesse had done on the Model M. They ended up having a race between a BO and the newly converted Model M Crawler. Wouldn’t you know it the Col won and it wasn’t because he was the boss, the BO has a faster gear ratio. Upon completing the Model M conversion, Deere and Company made an offer to purchase Lindeman Power Equipment Company. This put Jesse up against that brick wall again because the Federal Trade commission was about to step in due to the Deere-Ferguson rivalry. Jesse knew he could still make the deal with Deere and not include the plow or the hop picker. Jesse and Joe purchased 10 acres of property on South First Street and started Northwest Equipment Company in order to finish the already placed orders for the plows and hop pickers. Deere and Company took control of the plant on January 1, 1947. On December 28th prior to the takeover, the steel foundry caught on fire and burned to the ground (a $50,000 loss that was covered by insurance). The rest of the plant was not damaged.

The plant was sold for $1,147,340.18 with Jesse receiving the bigger portion along with stocks in Deere and Company. Part of the deal was that Jesse move to Moline and head up a development department. Jesse went back to Moline for a short time. Neither he nor his wife, Jane, liked it back there. He went to the Colonel and told him they were going to have to back out of the whole merger. The Colonel said, “hold on now. . . you go back to Yakima and head up the engineering and just come back to Moline two or three times a year.” So that is what Jesse did until Deere closed the plant in Yakima.

along with stocks in Deere and Company. Part of the deal was that Jesse move to Moline and head up a development department. Jesse went back to Moline for a short time. Neither he nor his wife, Jane, liked it back there. He went to the Colonel and told him they were going to have to back out of the whole merger. The Colonel said, “hold on now. . . you go back to Yakima and head up the engineering and just come back to Moline two or three times a year.” So that is what Jesse did until Deere closed the plant in Yakima.

Shortly after JD took over the operation the last of the BO Crawlers rolled off the assembly line.

Shortly after JD took over the operation the last of the BO Crawlers rolled off the assembly line.

Once back in Yakima Jesse designed the tool carrier known as the Yakima Hitch. They had three versions before it was finalized, adapting it to the “A,B, & G Models”

When the MC had been finalized and production was started, the orders for crawlers that came from the West coast were assembled in Yakima, the ones for the East coast were assembled back at John Deere. All the crawler parts were made in Yakima and shipped back East for them to assemble.

Eventually all the crawlers were assembled back East. John Deere closed the Yakima plant in 1954.

Eventually all the crawlers were assembled back East. John Deere closed the Yakima plant in 1954.

Jesse and Joe elected not to go with them and took over the operation of Northwest Equipment. By that time all the orders for the Hop Picker had been filled, and Jesse had turned over the rights to his cousin, Maurice Boseck. All but about 1,500 to 2,000 of the plows had been shipped and Ferguson had gone to a bigger tractor, a 2 bottom plow was then needed. Jesse elected not to build one, so Ferguson canceled the rest of the order with a fair severance check.

Jesse and Joe elected not to go with them and took over the operation of Northwest Equipment. By that time all the orders for the Hop Picker had been filled, and Jesse had turned over the rights to his cousin, Maurice Boseck. All but about 1,500 to 2,000 of the plows had been shipped and Ferguson had gone to a bigger tractor, a 2 bottom plow was then needed. Jesse elected not to build one, so Ferguson canceled the rest of the order with a fair severance check.

Jesse not only was a brilliant engineer, but also a journeyman pattern maker. He was constantly thinking of easier and more efficient ways to operate machinery. If he had an idea in the middle of the night, he would get up, go down to the plant, draw it up, make a pattern for casting it, and the next day it was cast and on the production line. In 1954 when Deere closed the Yakima Plant Joe was asked to move to the Midwest as sales manger of one of their plants in that area. Jesse’s love was in the designing and building of equipment, not in the running of a company so he turned the day to day running of Northwest Equipment over to Joe. This suited him fine, he didn’t mined dealing with the people and employees and managing it until its sale on March 1, 1982.

Northwest was mostly building fruit handling equipment by the time Jesse and Joe took over operations. Jesse had designed an apple sizer on his off time at John Deere. It had plastic cups on parallel bars and as they went down the adjustable rails they would spread apart and let the apple down onto a conveyor belt and off to be packed.

The Auto-bagger was a good selling item for them. It was used mostly by big supermarkets and warehouses to re-bag apples, potatoes, onions.

Jesse then built a rotary tiller. There was a Howard tiller already being built, but Jesse knew he could improve on it. He figured it would work better with belts than a gear drive like Howard had. They tried all different belts, mostly they didn’t hold up until finally Orie Durland (Jesse’s top man) tried the cheapest belts he could find, then they worked out very well. They eventually built them from 4 foot to 22 foot wide. Jesse also built a three point hitch, along with a PTO to go onto a Caterpillar tractor, so they too could use the rotary tiller he had developed.

They had different versions in each of the models: bedders for tilling and re-forming beds for planting, cultivators with tunnels to protect the plants as they tilled the weeds, reverse till to corrugate alfalfa. There was a model to work in the vineyards, its gear case was inside the main housing so they could get down the rows and get close to the vines. Another one was the Model K, it was a lot smaller and it was a

They had different versions in each of the models: bedders for tilling and re-forming beds for planting, cultivators with tunnels to protect the plants as they tilled the weeds, reverse till to corrugate alfalfa. There was a model to work in the vineyards, its gear case was inside the main housing so they could get down the rows and get close to the vines. Another one was the Model K, it was a lot smaller and it was a direct drive with a slip clutch like the Howard. It didn’t do as well as the other models because in the Yakima Valley there are a lot of rocks, and the little K just wasn’t tough enough. With the bigger horse power able to till deeper, the Model L was built. With the Model R & RB normal tilling depth was 6 inches with the L model it went down to 12 inches On a few of them Jesse added an engine for more power. There was one Model G built and rented out to Harvey Beauchene and his son MY (Myron) that did custom land clearing. The depth of its till was between 12 & 18 inches. A local farmer had an idea for weeding the beet fields. It was developed at NWE Co., this was also built in widths from 4 to 20 Feet.

direct drive with a slip clutch like the Howard. It didn’t do as well as the other models because in the Yakima Valley there are a lot of rocks, and the little K just wasn’t tough enough. With the bigger horse power able to till deeper, the Model L was built. With the Model R & RB normal tilling depth was 6 inches with the L model it went down to 12 inches On a few of them Jesse added an engine for more power. There was one Model G built and rented out to Harvey Beauchene and his son MY (Myron) that did custom land clearing. The depth of its till was between 12 & 18 inches. A local farmer had an idea for weeding the beet fields. It was developed at NWE Co., this was also built in widths from 4 to 20 Feet.

The Outrigger was a small tiller to till around trees. The trip arm would come in contact with a tree and that would apply a brake that would make it swing back away from the tree, thus the more pressure on the arm, the quicker it came back. Most units were mid mounted until there were so many tractor models coming out that Jesse could not keep up with the new mounts so he went to a three point mount only.

In the early 80s, Jesse and Joe sold the company to a couple of guys that were in the printing business and didn’t know any thing about manufacturing. Joe was ask by the new owners to remain as sales manager in which position he remained until his death on September 29, 1982. The new owners didn’t like the hitch for the Caterpillar because of a few warranty problems, instead of fixing the defects literally threw it into the scrap. They ended up running the company into the ground, splitting it up and selling it off.

Jesse had retired, Joe had passed away about a year after they sold the company. Jane, Jesse’s wife, knew that Jesse wanted to get back to work so she suggested that he and his son and grandson do what he had been thinking and talking about. So he went to the scrap yard and bought all the hitch parts he could find, using them to start Lindex Company. After Jesse had established Lindex, he contacted the dealers he had before, letting them know the hitch was available. One of the dealers was “Tenco Tractor” of Sacramento, CA. When one of the first Challenger 65 tractors was being tested there, it was having problems with steering with the implement in the ground. Wes McKeen (Tencos’ main salesman)who was well familiar with the Lindex hitch, told Pat Shook, the Caterpillar engineer who was doing the testing, about the Lindex hitch and he contacted Jesse. Jesse jumped at the chance to work on a new project especially this one. He had read all about the rubber tracked CAT and had said that if that type rubber had been available when he built the BO Crawler he would have used it also. Caterpillar had the drawings and a Challenger 65 sent out. This was in 1987 when Jesse was 88 years young. As he told me more then once “this is my golf game”. Obviously he loved it.

About a year after starting Lindex Jesse needed someone to manage it for him and I was very happy for the chance to work for him again. Shortly after I started back to work with Jesse, Jerry Searl, one of the owners of Edwards Equipment Co., came by and said he had been approached by John Deere about making a hitch to fit on their Model G series crawlers and he wasn’t interested, so Jesse designed a hitch and PTO for it. Now he was back with JD.

Jesse was honored by the local tractor club and was the Grand Marshal at their annual show in August 92. They were also hosting the nationals that year, the Lindeman Crawler was the featured tractor. He was pulled in the parade by a Lindeman Crawler which had been driven out from Ollie, IA for the honor. It was owned and driven by Harold Schultz.

Jesse also was interviewed by Randy Leffingwell for a chapter in “A History of the John Deere Tractor”, a book

he was writing. Jesse passed away shortly after, on September 10, 1992, one month prior to his 93rd birthday.

yes it was bill moore.

very interesting web site. I enjoyed reading it. an 86 year old friend passed away the other day and willed me his john deere m c. I grew up on a farm and as a kid we had a model m. any how keep up the good work. p s- in about 1987? I was in yakama wa for the first challenger class for n c machinery. I was with an n c salesman and he took me to dinner and I got to meet one of the lindemans in a restaurant one night. I don’t remember his name but he was in his 80’s. thanks larry watters

Thanks Larry for the pat on the back about the site. You must have went to dinner with Bill Moore from NC Machinery. Yes that must have been Jesse Lindeman you met, in 1987 he would have been 87 years young and still going strong, he passed away still sharp, one month before his 93rd birthday in 1992.

Love the black and white photos. As a suggestion, I would have to say the more you can put on your website the better!

thanks for the pat on the back, I plan to upload all the photos that I have, I hope to be done sometime this winter.

I am a JD Lindeman owner #334614.

Here is a link to it…. https://www.youtube.com/watch?v=5xYh4zTEZjw

Would be happy to help you clean those photos up.

I am versed in Photoshop, had a marketing, graphics and printing outfit with 22 employees at one time.

I can take the largest size photos you have, clean them up and re-size them for faster web loading, and if you want to give them away in the larger format, you can have a reference section that matches the larger size photo for downloading.

I noticed the photo on the home page of your site takes some time to load…. this is an easy fix.

If you are doing your own website stuff you can fix it or if you have a web guy doing it, he may be able to optimize them for you.

Anyway, good job on the site and bringing all this info to one spot.

Do you have plans to include a Post for Things ([parts and whole tractors) for SALE?

That would be sweet.

Thanks again,

Jim Alberti

Thanks Jim for the offer but as of right now you are the only one that has mentioned that the photos load a little slow. I am interested in knowing how to make it possible for anyone that would like the photos to download them. I haven’t found a way to do it yet in Word Press, if you can help with that it would be great.